TR-6SF servo terminal machine (10-300 square mm)

- Model

- TR-6SF

Item specifics

- Power

- AC220V/50HZ,

- Application

- TR-6SF servo terminal machine (10-300 square mm)

- Feature

- Stable Performance

- Warranty

- 1year

- Contact

- Coco 0086-18666170785

Review

Description

TR-6SF servo terminal machine (10-300 square meters)

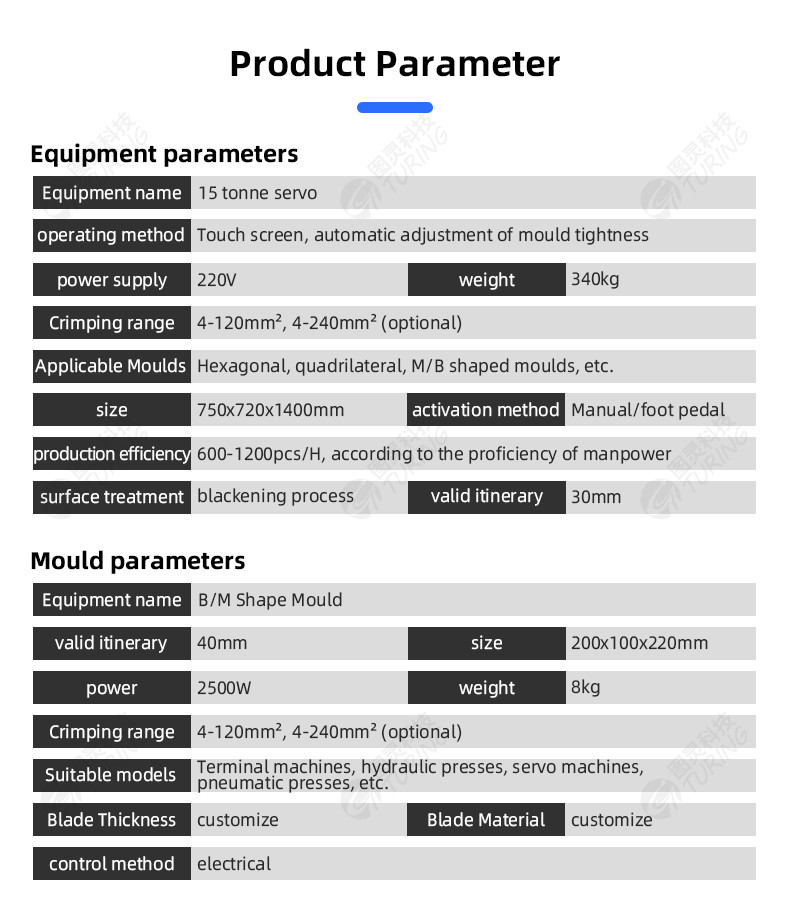

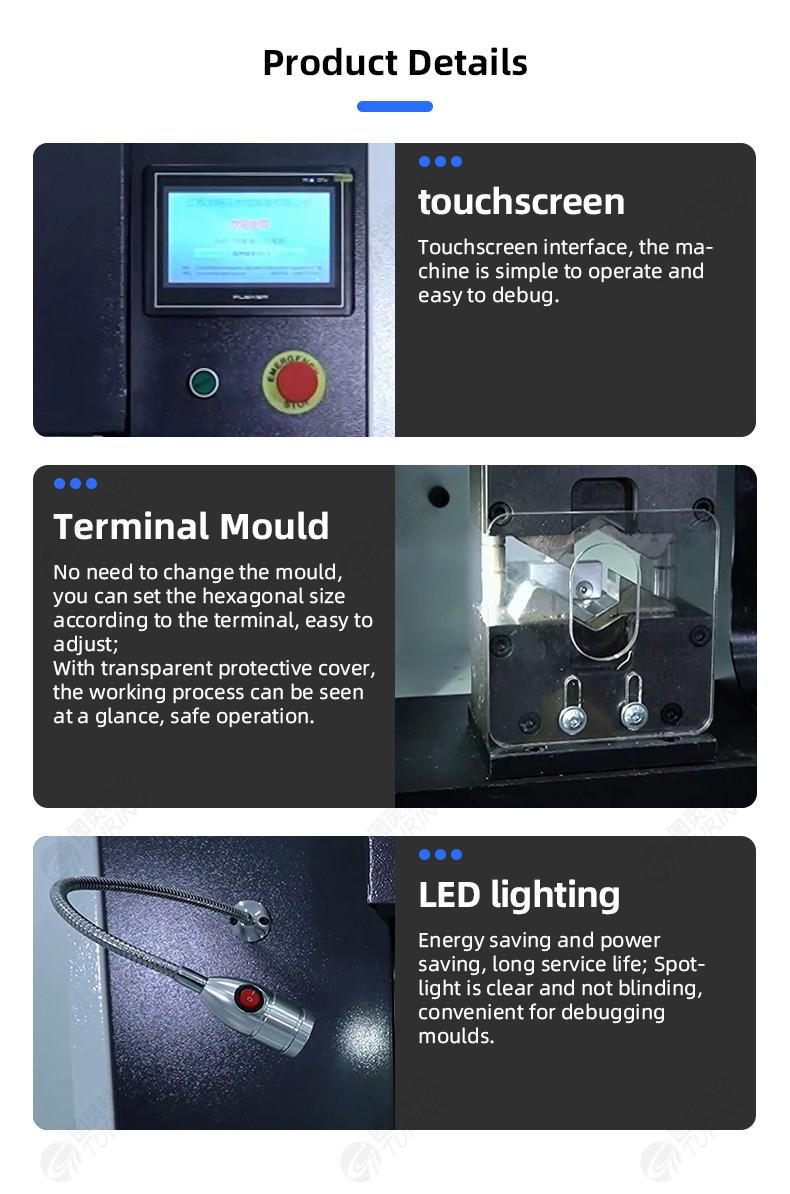

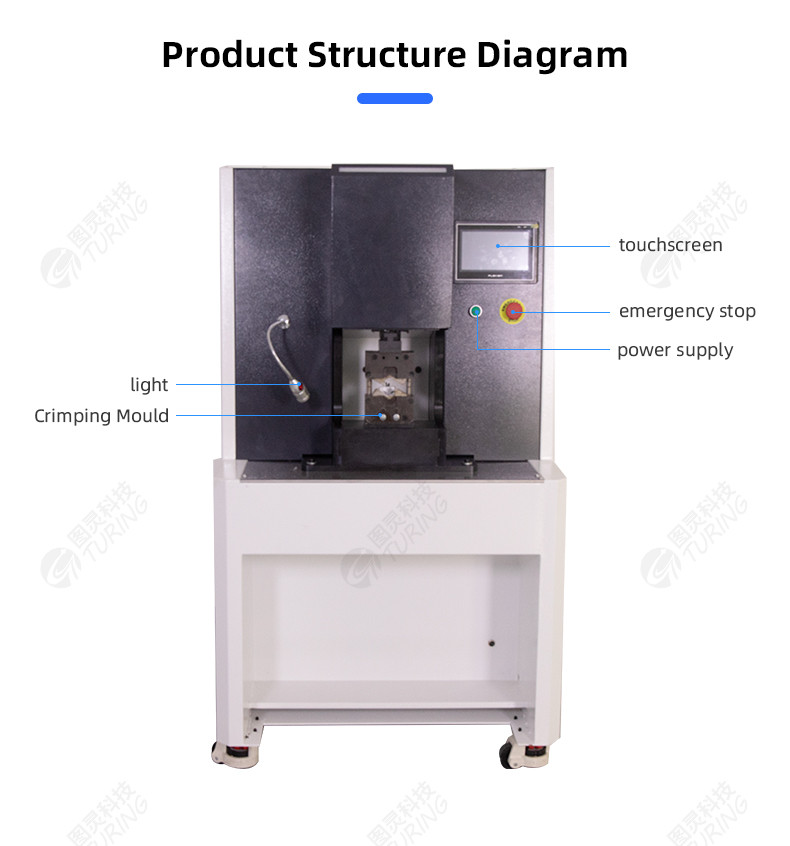

Operating method:Touch screen, automatic adjustment of mould tightness

Power supply:220V

Size&Weight:750x720x1400mm,340kg

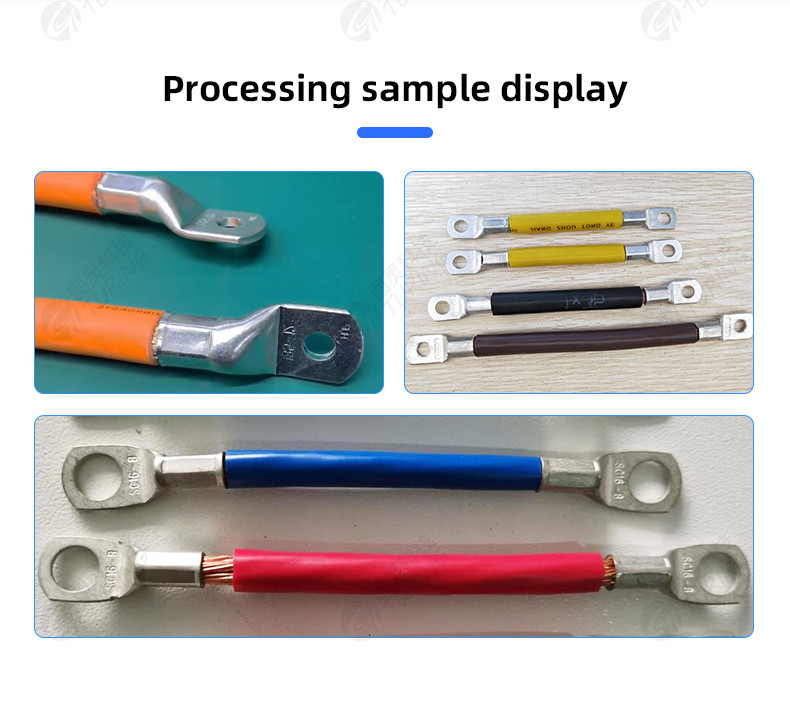

Crimping range:4-120mm², 4-240mm² (optional)

Applicable Moulds:Hexagonal, quadrilateral, M/B shaped moulds, etc.

Activation method:Manual/foot pedal

Production efficiency:600-1200pcs/H, according to the proficiency of manpower

Surface treatment:blackening process

Valid itinerary:30mm

Characteristics1, This is a servo type positive hexagonal mould-less crimping machinemainly suitable for new energy configuration line, charging pile andcharging gun wiring harness processing, automobile battery cable, distri-bution cabinet cable and other large square various types of copper pipeterminals, sealing SC terminals and other terminals crimping, no need tochange the mould, you can set the hexagonal size according to the termi-nals, easy to adjust, safe operation.The cross-section after crimping is hex-agonal, and the crimp size can be set and stored at once in the programmewithout manual adjustment. At the same time can also be installedfour-side tubular free mould, by replacing different moulds can achieve dif.ferent crimping effect.

2、This machine adopts high-precision servo motor drive, colour touchscreen operation interface, the opening size of the mould and crimp sizecan be set in the program, a machine can crimp a variety of different sizesof terminals, just set the crimping parameters in the touch screen, neitherneed to change the mould, nor need to adjust the screws.

3, the advantages of the equipment is no need to change the mould, faststable, high efficiency, the use of open mould crimp can be completelyopen, suitable for intermediate wiring, compact structure, space-savingnoise.Fulltouch-screen operation, delicate and beautiful appearance,placed in the workshop, especially to highlight the high-end atmosphere.upgrading, subsequent crimping only need to call out the relevant proce-dures can be crimped, the whole with the serice motor control, Taiwanscrew drive, PLC full touch-screen operation, the operating interface screenis wide, the work does not require a gas source, directly plugged into thepower can work, fast speed.Powerful safety and protection features,crimping shape standard, beautiful and no burrs, such a good product isthe greatest demand in the market, and not easy to eliminate the goodproducts.