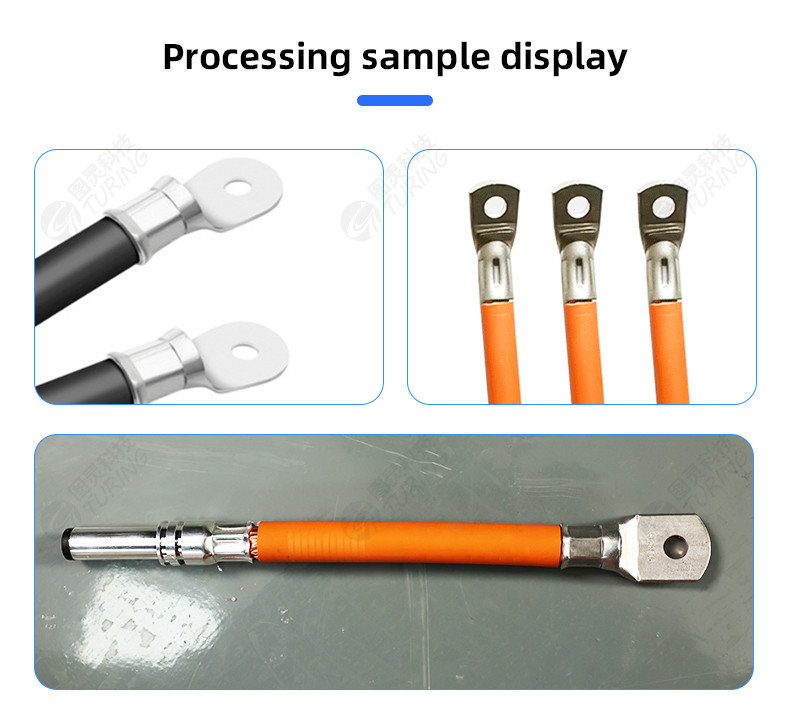

TR-30TS 30T CNC servo terminal crimping machine

- Model

- TR-30TS

Item specifics

- Power

- AC220V/50HZ,

- Application

- Intelligent Servo Terminal Crimping Machine

- Feature

- Stable Performance

- Warranty

- 1year

- Contact

- Lily 0086-13715588365

Review

Description

TR-30TS 30T CNC servo terminal crimping machine

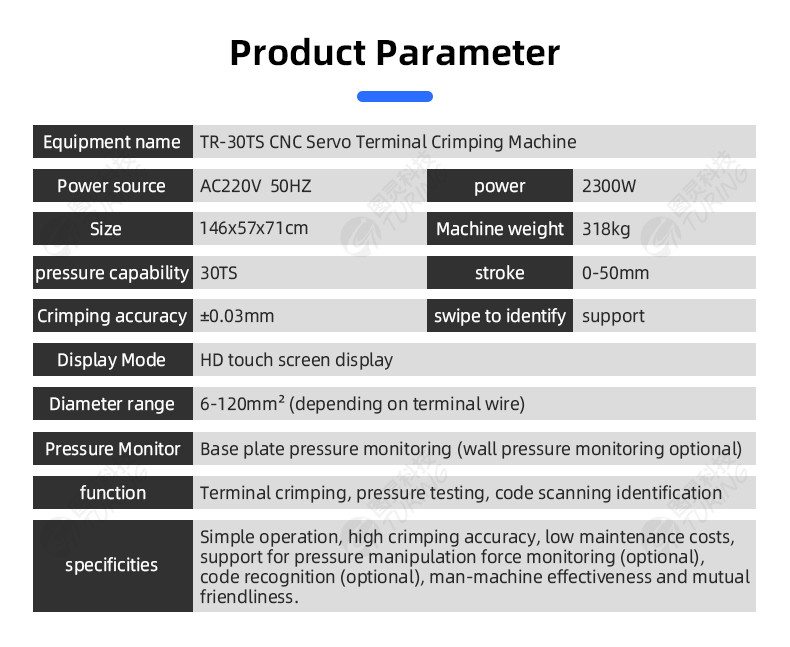

Power source:AC220V 50Hz , 2300W

Size&weight:146x57x71cm,318kg

Pressure capability:30TS

Stroke:0-50mm

Crimping accuracy:±0.03mm

Swipe to identify:support

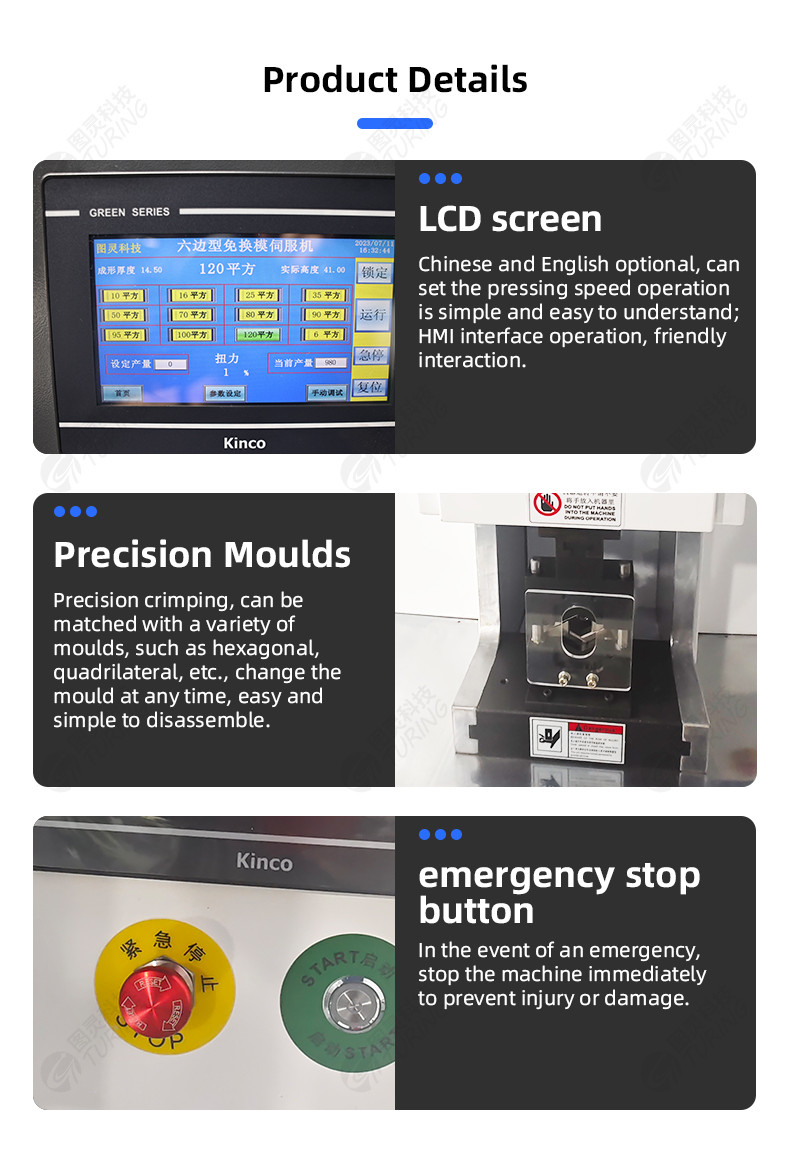

Display Mode:HD touch screen display

Diameter range:6-120mm² (depending on terminal wire)

Pressure Monitor:Base plate pressure monitoring (wall pressure monitoring optional)

function:Terminal crimping, pressure testing, code scanning identification

specificities:Simple operation, high crimping accuracy, low maintenance costs,

support for pressure manipulation force monitoring (optional),

code recognition (optional), man-machine effectiveness and mutual

friendliness.

Functional features

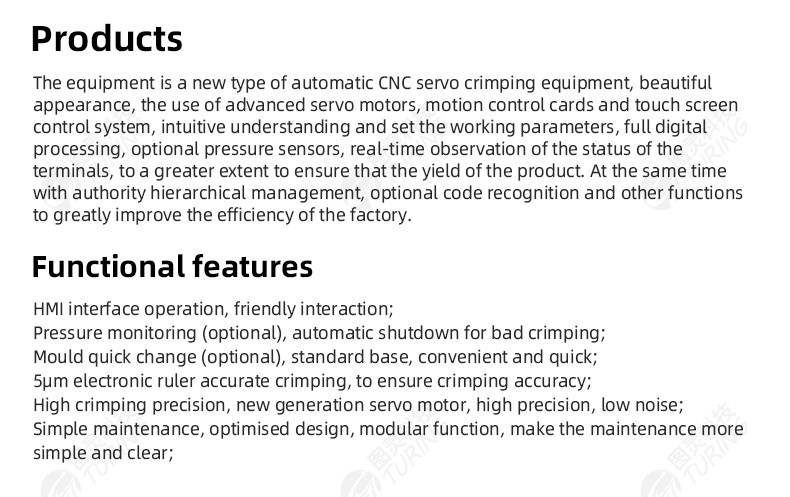

HMI interface operation, friendly interaction;

Pressure monitoring (optional), automatic shutdown for bad crimping;

Mould quick change (optional), standard base, convenient and quick;

5µm electronic ruler accurate crimping, to ensure crimping accuracy;

High crimping precision, new generation servo motor, high precision, low noise;

Simple maintenance, optimised design, modular function, make the maintenance more simple and clear;

Products

The equipment is a new type of automatic CNC servo crimping equipment, beautifulappearance, the use of advanced servo motors, motion control cards and touch screencontrol system composed of intuitive understanding and set the working parameters ofthe full digital processing, optional pressure sensors, real-time observation of the statusof the terminals, to a greater extent to ensure that the yield of the product. At the sametime with authority hierarchy management, optional code recognition and otherfunctions to greatly improve the efficiency of the factory.

Functional features

HMl interface operation, friendlyinteraction;Pressure monitoring (optional),automatic shutdown for bad crimping;Mould quick change (optional), standard base, convenient and quick;5um electronic ruler accurate crimping, to ensure crimping accuracy;High crimping precision, new generation servo motor, high precision, low noise;Simple maintenance, optimised design, modular function, make the maintenance moresimple and clear;

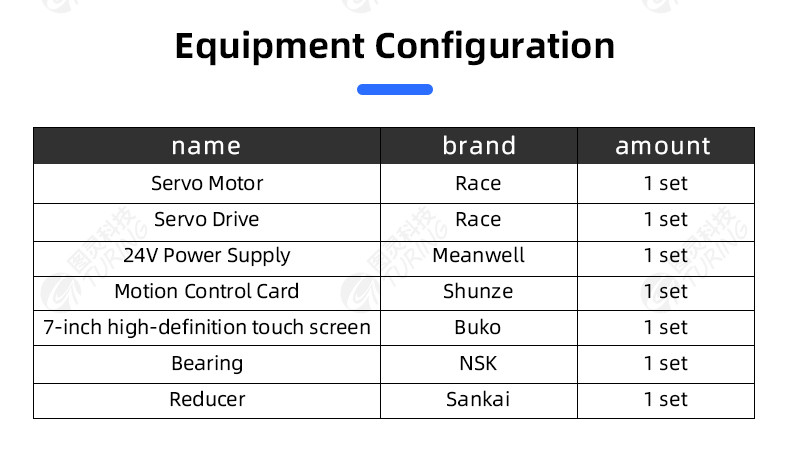

SERVO MOTOR DRIVE

Overcome the traditional motor out-of-step problems,to achieve high-precision operation, with a fast response Simple manipulation,low noise, low energy consumption and so on.

INDUSTRIAL COMPUTEROPERATION

Touch screen operation, control system integration,data traceability Industry 4.0, can be docked with thefactory MODBUS system three levels of authority settings,more reliable parameter settings, can store 120 kinds ofprocessing parameters program, convenient debugging