TR-NY01 CNC Nylon Mesh Pipe Threading Machine

- Model

- TR-NY01

Item specifics

- Power

- AC220V/50HZ,

- Name

- Wire threading braided mesh machine

- Feature

- Stable Performance

- Warranty

- 1year

Review

Description

TR-NY01 CNC Nylon Mesh Pipe Threading Machine

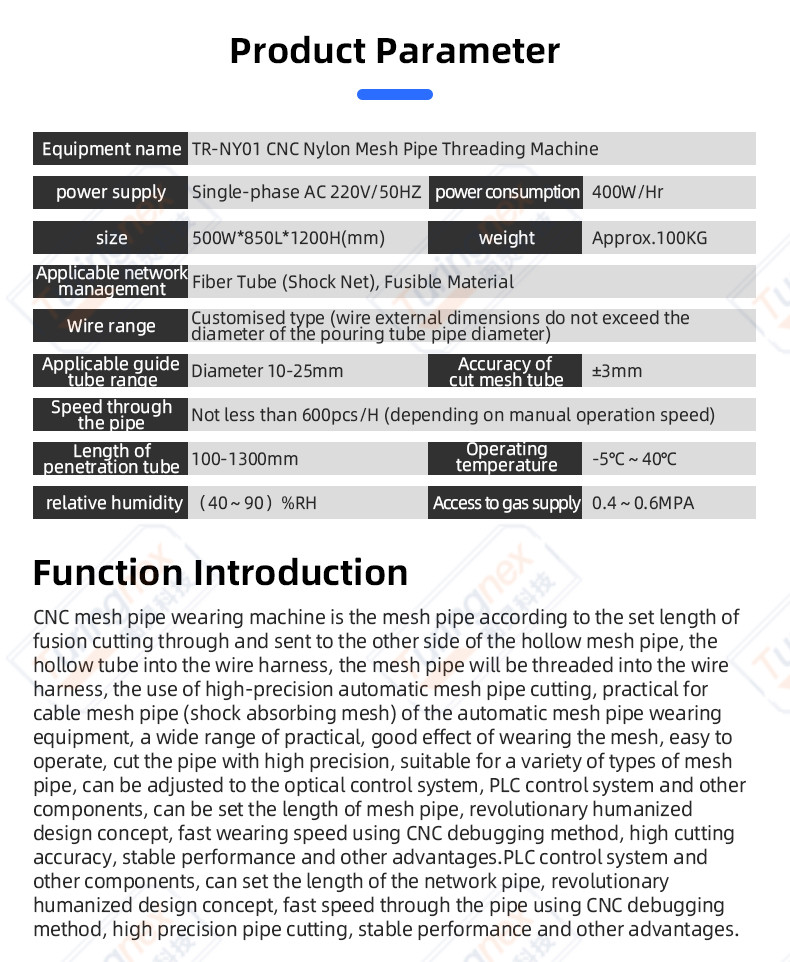

Equipment name:TR-NY01 CNCNylon Mesh Pipe Threading Machine

power supply:Single-phase AC220V/50HZ

size:500W*850L*1200H(mm)

power consumption:400W/Hr

weight:Approx.100KG

Wire range:Customised type (wire external dimensions do not exceed thediameter of the pouring tube pipe diameter)

Applicable network:Fiber Tube (Shock Net),Fusible Materialmanaqement

Applicable guidetube range:Diameter 10-25mm

Speed throughthe pipe:Not less than 600pcs/H(depending on manual operation speed)

Length of penetration tube:100-1300mm

relative humidity:(40~90)%RH

Accuracy of cut mesh tube:±3mm

Operatingtemperature:-5℃~40℃

Access to gas supply:0.4~0.6MPA

Function Introduction

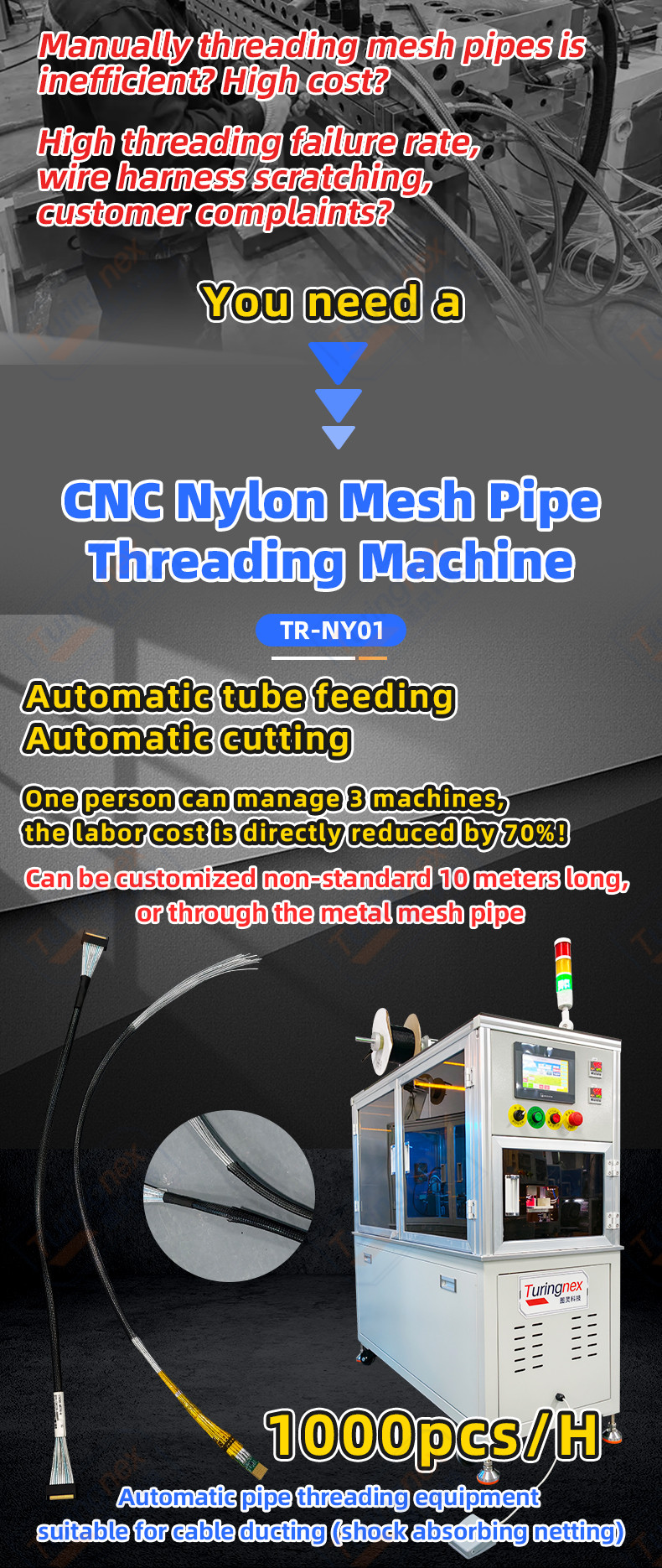

CNC mesh pipe wearing machine is the mesh pipe according to the set length of fusion cutting through and sent to the other side of the hollow mesh pipe, the hollow tube into the wire harness, the mesh pipe will be threaded into the wire harness, the use of high-precision automatic mesh pipe cutting, practical for cable mesh pipe (shock absorbing mesh) of the automatic mesh pipe wearing equipment, a wide range of practical, good effect of wearing the mesh, easy to operate, cut the pipe with high precision, suitable for a variety of types of mesh pipe, can be adjusted to the optical control system, PLC control system and other components, can be set the length of mesh pipe, revolutionary humanized design concept, fast wearing speed using CNC debugging method, high cutting accuracy, stable performance and other advantages.PLC control system and other components, can set the length of the network pipe, revolutionary humanized design concept, fast speed through the pipe using CNC debugging method, high precision pipe cutting, stable performance and other advantages.