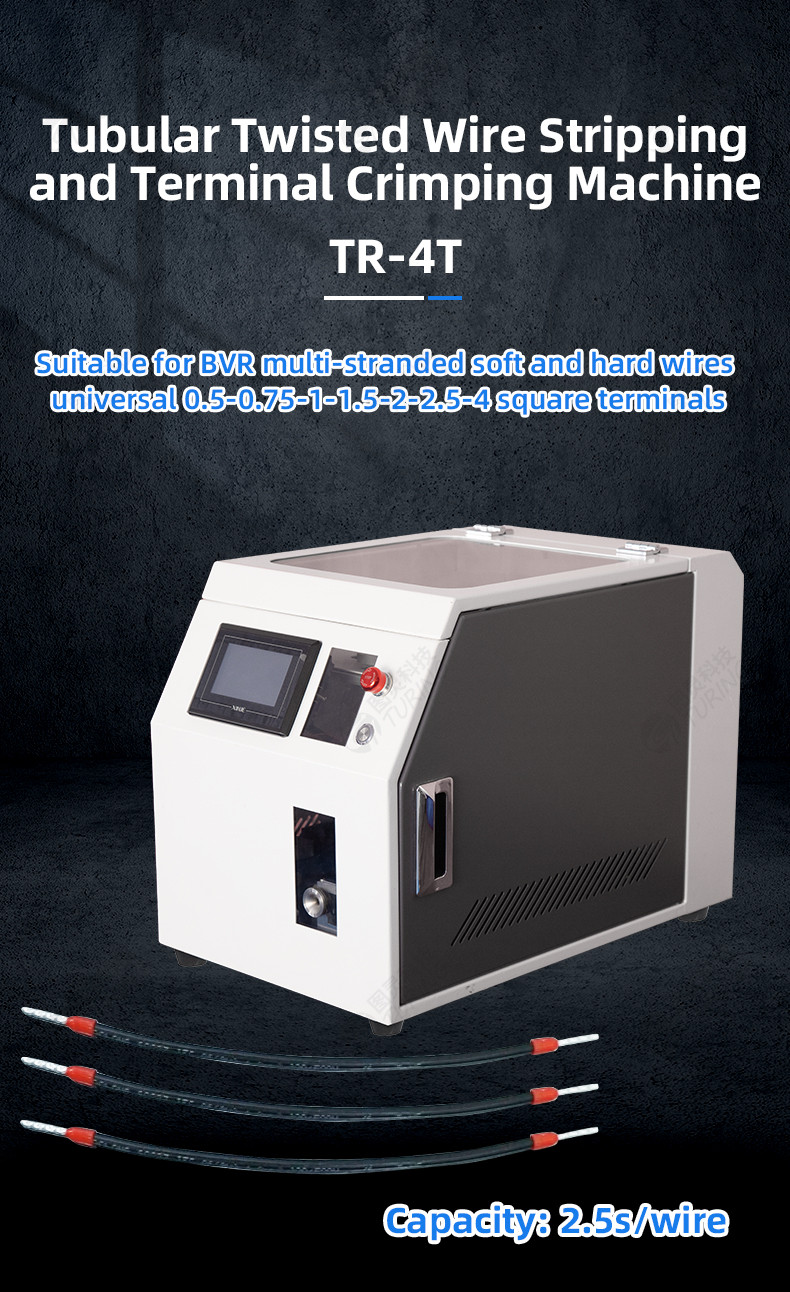

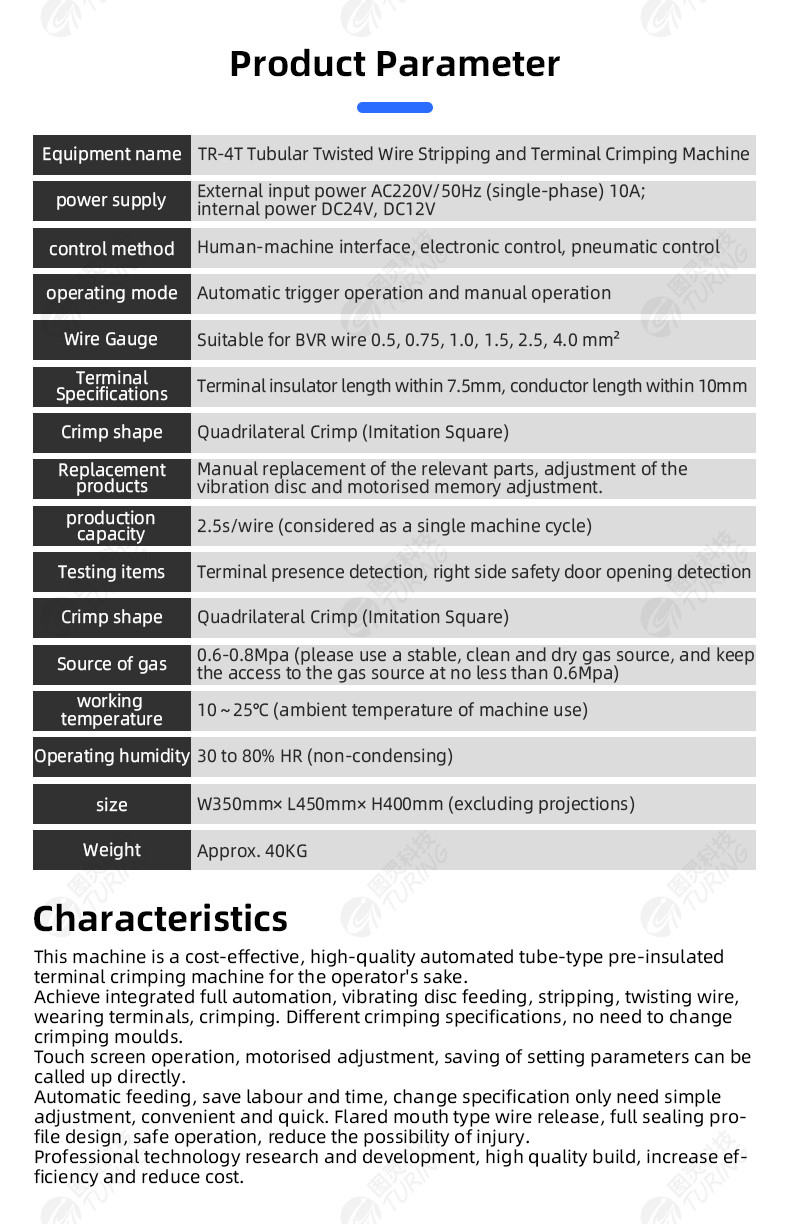

TR-4T Tubular Twisted Wire Stripping and Terminal Crimping Machine

- Model

- TR-4.0T

Item specifics

- Power

- AC220V/50HZ,

- Application

- wire stripping and terminal crimping machine

- Feature

- Stable Performance

- Warranty

- 1year

- Control

- Servo and Step motor

- Contact

- Lily 0086-13715588365

Review

Description

TR-4T Tubular Twisted Wire Stripping and Terminal Crimping Machine

Characteristics

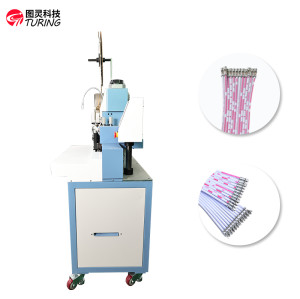

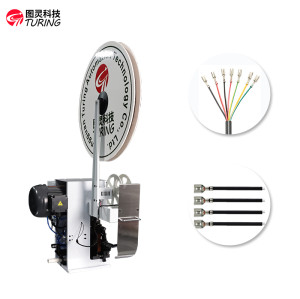

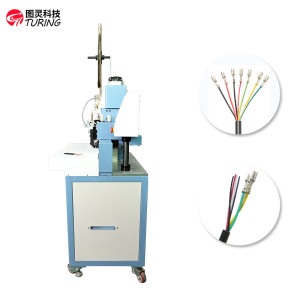

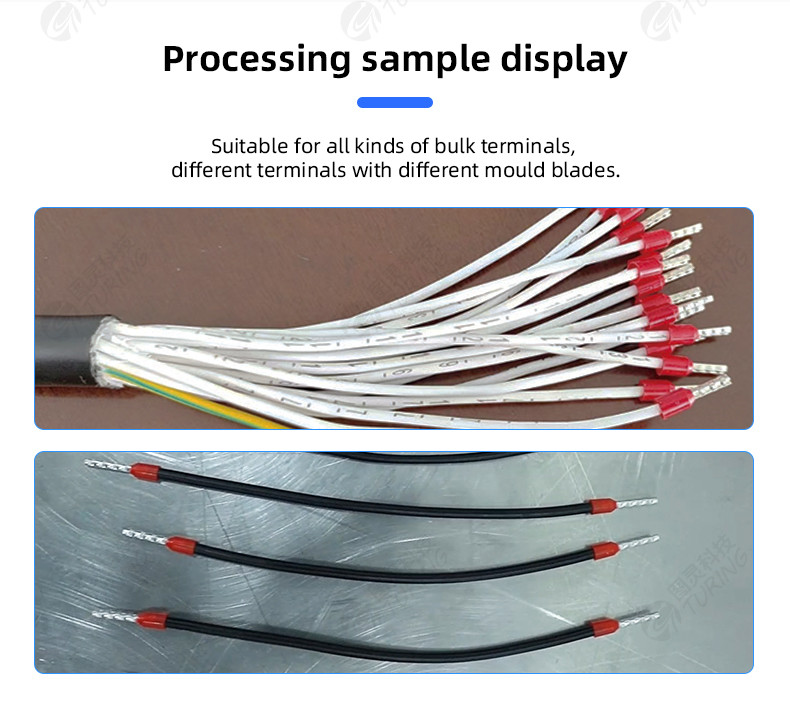

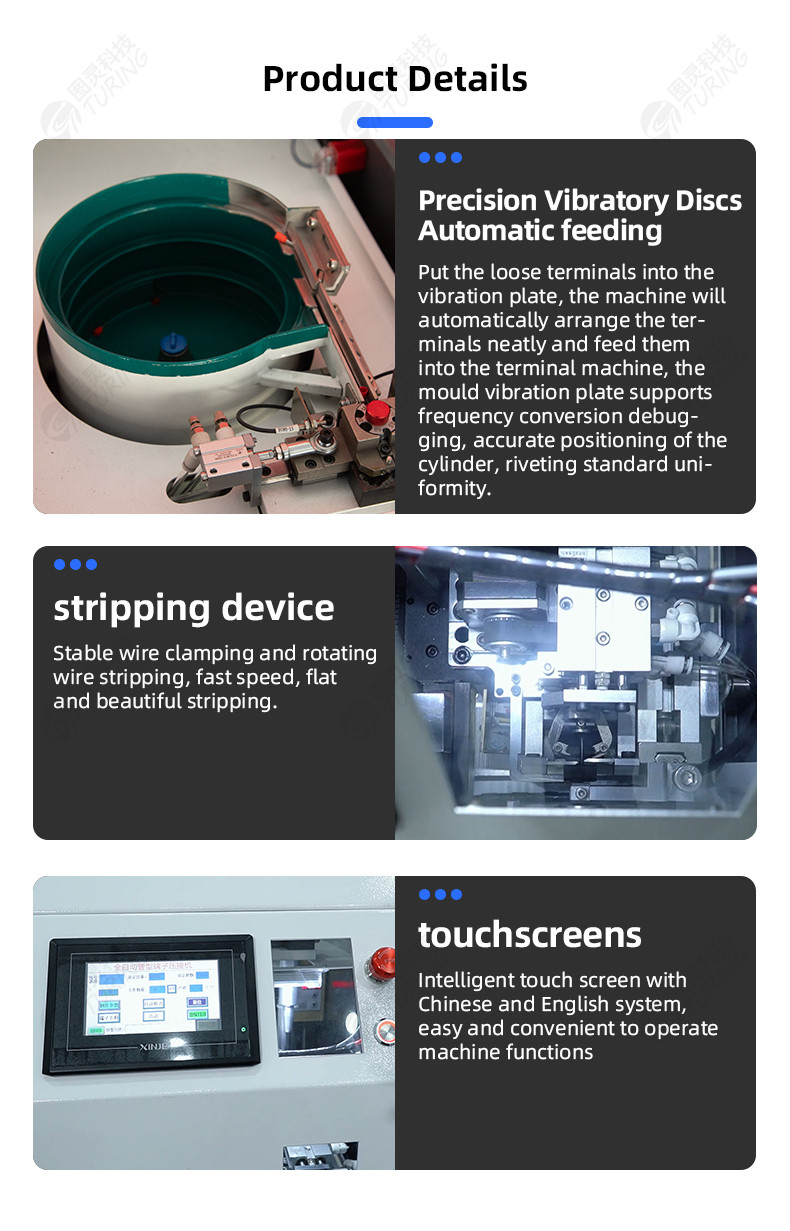

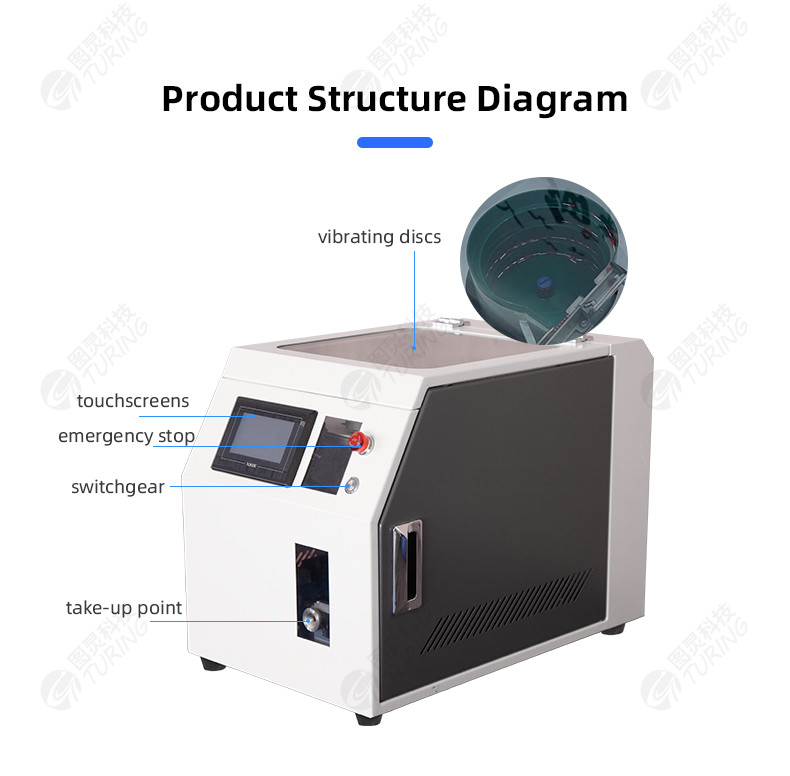

This machine is a cost-effective, high-quality automated tube-type pre-insulatedterminal crimping machine for the operator's sake.Achieve integrated full automation, vibrating disc feeding, stripping, twisting wire.wearing terminals, crimping. Different crimping specifications, no need to changecrimping moulds.Touch screen operation, motorised adjustment, saving of setting parameters can becalled up directly.Automatic feeding, save labour and time, change specification only need simpleadjustment, convenient and quick. Flared mouth type wire release, full sealing pro-file design,safe operation, reduce the possibility ofinjury.Professional technology research and development, high quality build, increase ef-ficiency and reduce cost.

Self-developed advanced procedures

automatic completion: wire feeding, wire straightening

cut flush, stripping, playing the end, put away the wire.

Capacity: about 5000-7000 terinals/hour (depending on the wire)