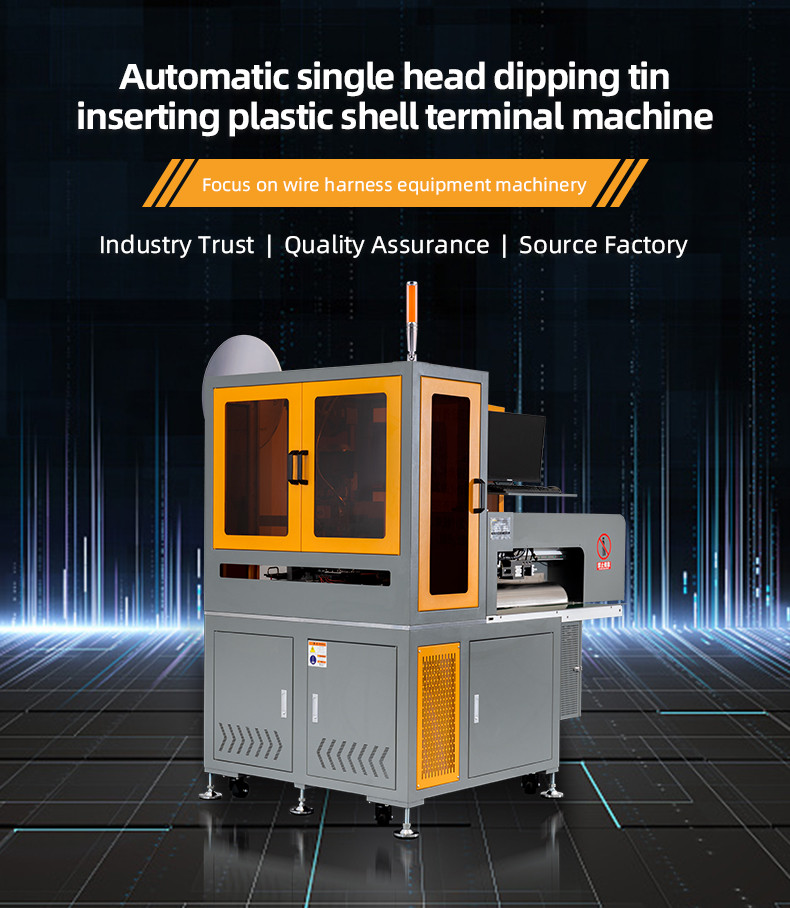

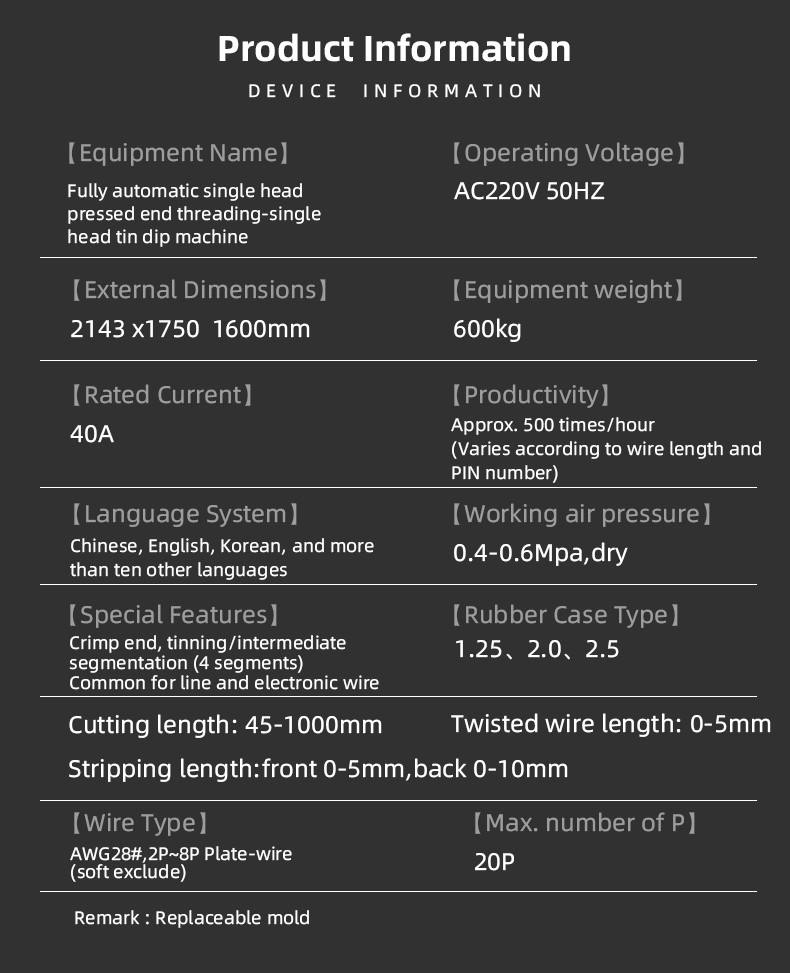

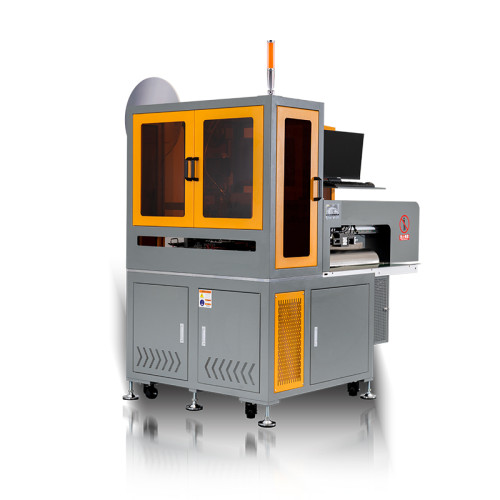

Fully Automatic Single Head Pressure Terminal End Insert The Shell Single End Tin Dipping Machine

- Model

- TR-JK1

Item specifics

- Power

- AC220V/50HZ, 300W

- Application

- terminal insert shell and tin dipping machine

- Feature

- Stable Performance

- Warranty

- 1year

- Control

- Servo and Step motor

- Contact

- Coco 0086-18666170785

Review

Description

Fully Automatic Single Head Pressure Terminal End Insert The Shell Single End Tin Dipping Machine

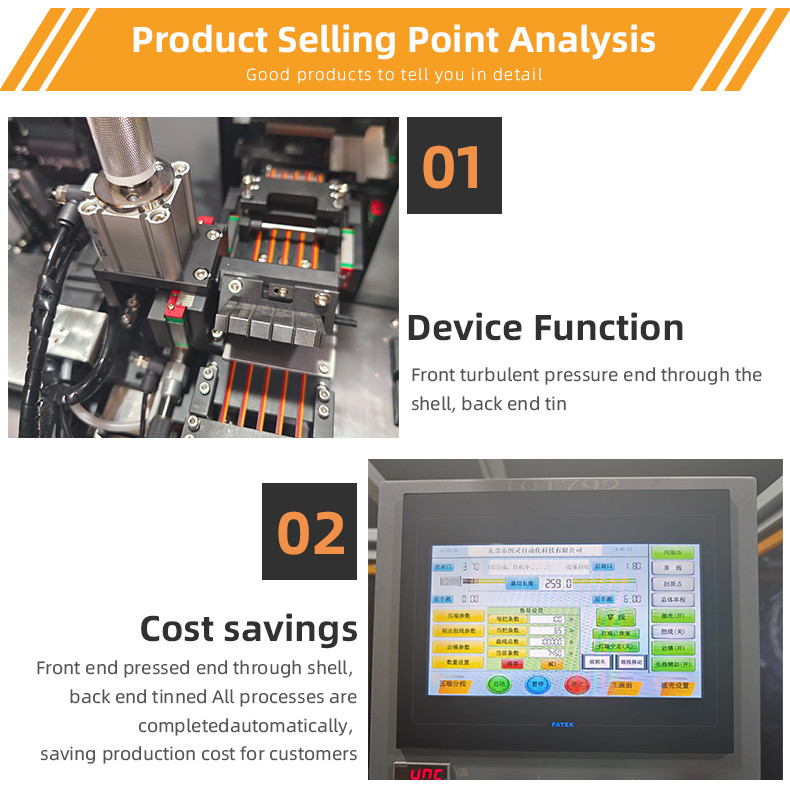

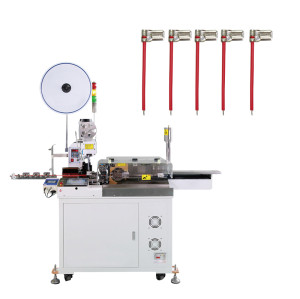

Equipment function: the front end is pressed through the shell, and the back end is dipped in tin

Cost saving: the front end presses through the shell, the back end dips in tin, and all processes are

automatically completed, saving production costs for customers.

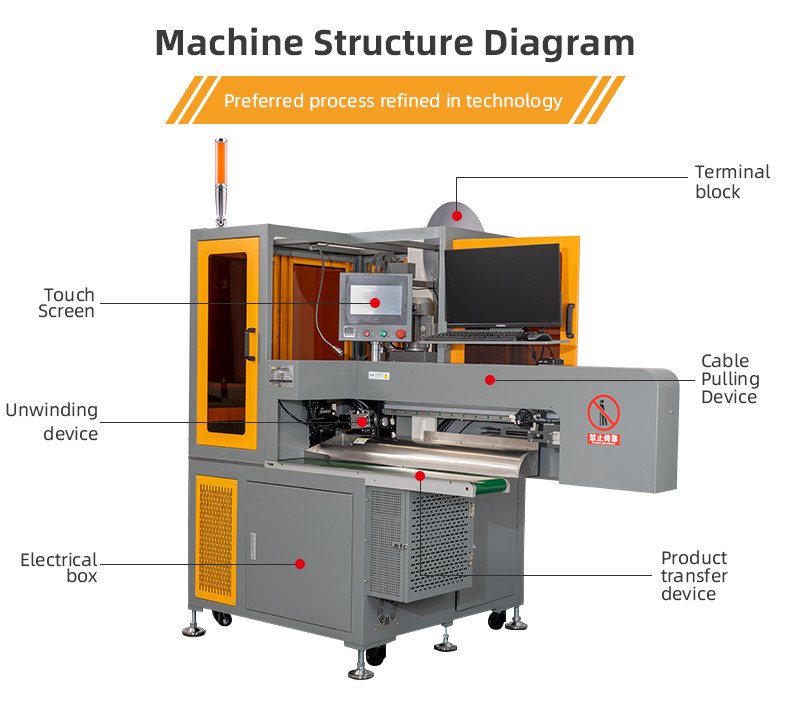

Good stability: The crimping end adopts eccentric shaft and cam structure, the crimping force of the terminal

is balanced, the crimping of the terminal is neat, and the consistency is good.

High precision: Servo motors are used to control cutting, peeling, pressure end positioning,

shell feeding, shell piercing, and precise positioning.

Simple operation: touch screen operation, easy parameter setting and operation, easy to understand at a glance,

ordinary employees only need simple training, and one person can operate several devices.

|

Product Name

|

TR-JK1 Automatic single head through shell dip tin machine

|

|

Crimping Machine Size

|

2108x1600x1600(mm)

|

|

Equipment weight

|

About 600KG

|

Working voltage | AC220V 50HZ |

|

Working pressure

|

0.5-0.7Mpa, dry AIR

|

Rated current | 40A |

Placement environment | The ground is flat and firm, dry, without sunlight |

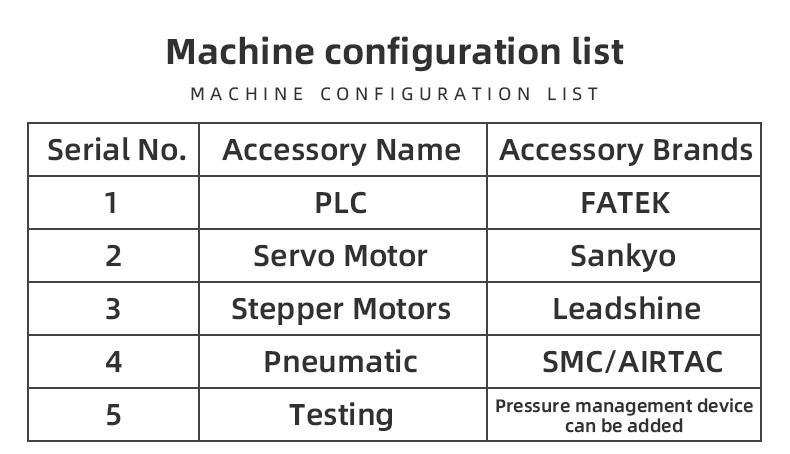

Control | Yonghong PLC |

Pneumatic | The whole machine is SMC brand |

Testing | Pressure management device can be added |

Efficiency | 400-500 times/h the machine can work 24 |

Cut length | 30-1000mm (length can be specified) |

Front stripping length | Peeling 0-10mm, twisted wire 2-6mm |

Rear peeling length | 0-5mm, pressure end, insert shell |

Rubber shell type | 1.25, 1.5, 2.0, 2.5, etc. |

P number of shell processing | Electronic wire 2P-12P, row wire 2P-5P |

Other functions | Strandable, up to 5 sets of stranded wires |

Wire type | AWG28# - 18# electronic wire, line wire |