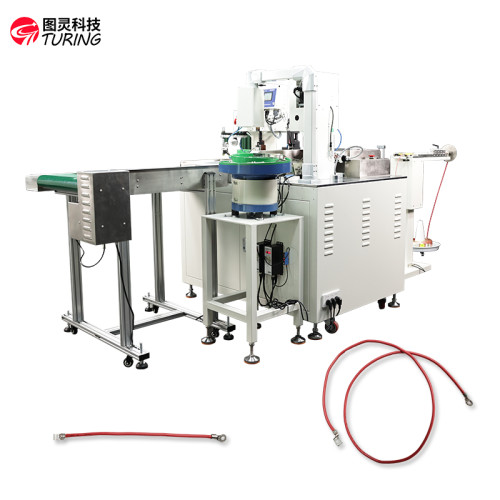

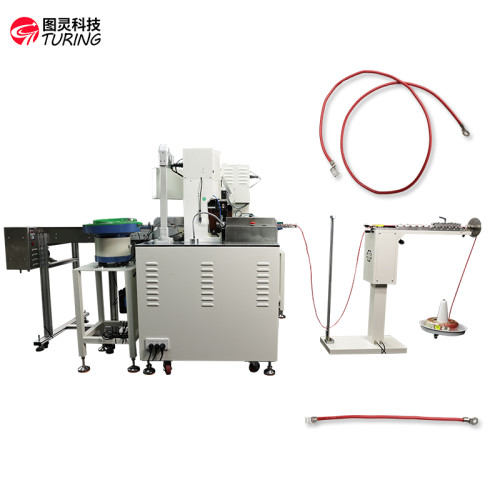

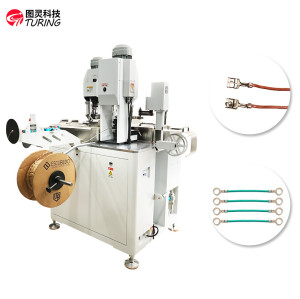

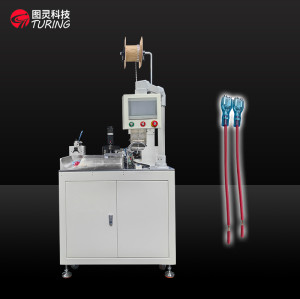

TR-DM070 Fully Automatic Double-head Bulk 3T Terminal Crimping Machine

- Model

- TR-DM070

Item specifics

- Power

- AC220V/50HZ,

- Application

- Double-head Terminal Machine

- Feature

- Stable Performance

- Warranty

- 1year

- Control

- Servo and Step motor

- Contact

- Lily 0086-13715588365

Review

Description

TR-DM070 Fully Automatic Double-head Bulk 3T Terminal Crimping Machine

Equipment features

1.Suitable for AV,AVS, AVSS, CAVUS, KVKI, UL and otherwire processing.

2. Servo motor crimping, high crimping precision up to0.01 mm.

3.With pre-compression and secondary crimpingfunction, reduce the probability of flying wire when thewire harness is introduced into the terminal.

4.One end can be crimped on the front side and theother end can be crimped on the back side

.5.Compatible with all kinds of moulds, can be equippedwith OTp lapanese clamping mould or Europeanclamping mould according to requirements, with strongversatility.

6.The terminal machine can be made of integrated castiron, sturdy and durable.

7.Cutting length, stripping depth, crimping height andother data can be controlled on the screen, easy to use.

8.components such as pressure monitoring system,CCDvisual inspection system,safety shield, wire feedingtake-up belt, MES system can be added.

detection unit

Terminal presence detection

Abnormal air pressure detection

Missing wire or kink detection

Tie-off/Total Reach Detection

Servo Motor Abnormal Detection

Poor terminal crimping(optional)Bad terminal appearance(optional)

Options

-Terminal feeding vibration disc

-Pre-feeding device

-Servomotor crimping

-Inverter motor crimping

-Safety guards

-Take-up conveyor

-MES industrial control system-Pressure management monitoring device-CCDimage detection device